公司簡介

斯派迪大事件

1、1997年成立廣州格麗特貿(mào)易有限公司,主營化工產(chǎn)品國內(nèi)貿(mào)易成批出售

2、2001年成立上海匯臣格麗特工貿(mào)有限公司,主營玻璃產(chǎn)品加工和貿(mào)易

3、2003年成立廣州格麗特建材有限公司,主營夾膠玻璃和熱轉(zhuǎn)印玻璃的加工

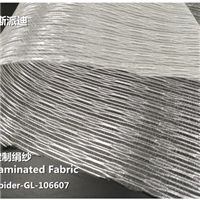

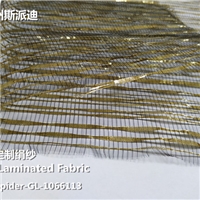

金屬蠶絲的染色印刷加工

4、2005年成立浙江義烏辦事處,主營化工產(chǎn)品的成批出售和銷售

5、2009年成立浙江公司,主營玻璃行業(yè)材料銷售,并成立長三角倉儲中心

6、2015年成立天津公司,主營玻璃行業(yè)材料銷售,并成立北方倉儲中心

7、2016年成立四川公司,主營玻璃行業(yè)材料銷售,并成立西部倉儲中心

8、2017年成立河北沙河工廠,主營淋浴房夾膠玻璃的生產(chǎn)加工銷售

9、2018年廣州印刷工廠搬至東莞,開創(chuàng)國內(nèi)較好寬幅彩膜印行業(yè)獨(dú)有模式。

印刷彩膜

? ? 公司引進(jìn)國外彩膜生產(chǎn)技術(shù):擁有全自動七色電腦印刷機(jī),電腦跟進(jìn)涂布機(jī),幅寬1.6米的印刷鍍膜鍍鋁機(jī),2米6色印刷機(jī)一臺,2.8米的凹版印刷機(jī),有經(jīng)驗(yàn)從事新型夾膠玻璃裝飾材料和建筑裝飾材料等開發(fā)生產(chǎn)。目前開發(fā)的各種版有1000多種,每月新開版20套至30套,可根據(jù)客戶要求進(jìn)行印刷,洗鋁,涂布加工各種寬幅的pvc膜、pet膜、 opp膜等。 主要尺寸可定制寬幅1米,1.54米,1.85米,2.2米,2.5米印刷彩膜,及各種寬幅底膜。工廠已經(jīng)通過國家環(huán)評,并符合國家產(chǎn)業(yè)政策標(biāo)準(zhǔn)生產(chǎn)。生產(chǎn)的膜具有附著力強(qiáng)、光澤度高、圖文清晰、層次分明、套色準(zhǔn)確、形象逼真、安全無害等優(yōu)勢和特點(diǎn),大大提高產(chǎn)品檔次和附加值,使產(chǎn)品更具市場競爭力。

Guangzhou Spider Laminated ?Material Co., Ltd., founded in 1998, Guangzhou, is a high-tech printing enterprise integrating R&D, design, production and sales.

The company has introduced advanced film production technology from abroad: full-automatic seven-color computer printing machine, computer tracking coating machine, 1.6-meter wide printing and aluminium plating machine, 2.8-meter gravure printing machine, specializing in the development and production of new glued glass decorative materials and building decorative materials.

At present, there are more than 1000 versions developed, which can print various wide PVC and PET films according to customers. The film produced has the advantages and characteristics of strong adhesion, high gloss, clear pictures and texts, clear hierarchy, accurate color registration, vivid image, safety and non-toxicity, which greatly improves the product grade and added value, and makes the product more competitive in the market.

Over the past 20 years, we have devoted ourselves to the research and development and innovation of various surface decorative materials, such as building materials, decoration, furniture and decoration. We have adhered to the tenet and idea of "science and technology leading, product innovation, honesty first, quality first". We have built professional teams, mastered core technology, devoted ourselves to technological innovation, led the development of the industry and continuously launched them. A variety of explosion-proof film and other products, enhance the taste of life, occupy the market opportunities.

Over the past 20 years, the company has provided all-round glued glass intermediate sandwich decorative materials for Chinese and foreign customers, and has become a supplier of the Chinese glued glass materials; the company's main products: silk yarn art, wire, metal mesh, fiber mesh, PET/PVC decorative film, gold foil film, aluminium wash film, photoelectric film. Marble film/paper;

? ?

? ? The company has imported foreign color film production technology: it has a full-automatic seven-color computer printer, a computer tracking coater, a 1.6-meter-wide aluminum plating machine for printing and coating, a 2.6-meter color printer and a 2.8-meter gravure printer,specializing in the development and production of new laminated glass decorative materials and building decorative materials. At?

present, there are more than 1,000 kinds of editions developed, and 20to 30 new editions are opened every month, which can be printed,aluminum washed, coated and processed with various wide-width pVc films, pet films, opp films, etc. according to customer requirements.The main dimensions can be customized with 1 meter wide, 1 .54 meter wide, 1.85 meter wide, 2.2 meter wide, 2.5 meter wide printed color film and various wide bottom films. The factory has passed the national environmental assessment and is in line with the national industrial policy standards for production. The produced film has the advantages and characteristics of strong adhesive force, high glossiness, clear picture and text, clear hierarchy, accurate color matching, vivid image,safety and innocuity, etc., greatly improves the product grade and added value, and makes the product more competitive in the market.